Finished Goods Food Waste Reduction

Finished Goods Food is wasted before reaching consumers baskets for many reasons, ranging from hard to manage quality root causes to managing excess inventory for product innovations or delisted products where there is a great opportunity for companies to invest in a stronger process and data-driven decision making.

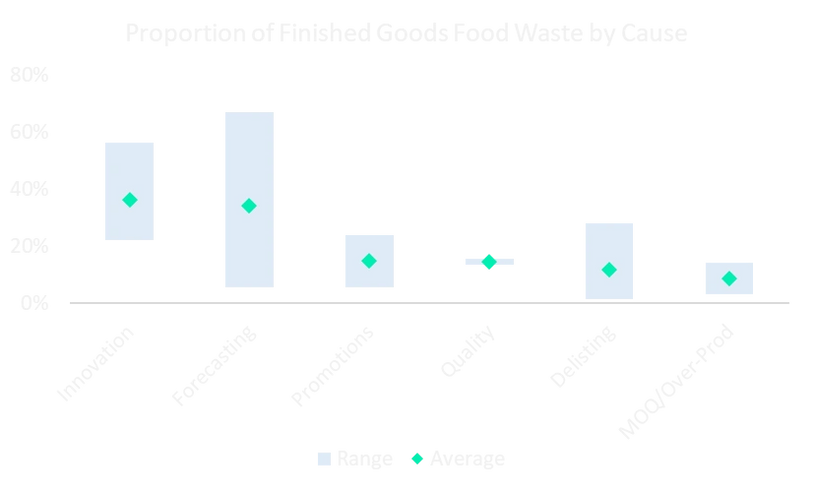

Through 4 finished goods food waste projects with Top 20 global food manufacturers, we have collated data on leading causes of finished goods food waste. In 3 out of 4 cases, innovation/new product development was the leading root cause, which we have a specific article on here. For this article though, we want to focus on the number one solution that all global food manufacturers must have in place – a way to track and manage residual inventory that is headed for waste and sell or donate it to avoid wastage. From the chart below, this type of solution can help mitigate over 80% of current finished goods waste.

Identifying Waste

While many companies think they have an effective process for tracking their inventory health, and what inventory is going to be wasted, our experience says that there is still much to be improved. Typical processes only flag inventory as potential waste when it is already approaching expiry, and with calculations that don’t actually tell you how many cases of a product you are expecting to waste.

At Purpose AI, we have developed a data model which combines current inventory data with the demand forecast to flag when inventory is at risk of being wasted, even when it has as much as 75% of its shelf life remaining. This earlier visibility of waste risks means you have far more options that you can take to mitigate this waste risk. As a result, you can often get much more value out of that inventory than if it sat in the warehouse for a few months and is then heavily discounted or donated.

Taking Action

Once you have identified inventory that you think is going to go to waste, the number 1 priority should be selecting an action to mitigate the waste risk. Our experience here says that this is a big hurdle, often taking many weeks and resulting in higher-value actions being closed off before they even get off the ground.

This is where Artificial Intelligence comes in. By looking at the actions your company has taken previously, and what the results of those actions were, it can predict what the likelihood of success, and the potential financial benefit, would be from the actions you have available. This needs to be partnered with rules around when different actions can be taken, such as donating a product needs 2 weeks left before expiry, and specific rules for actions such as it costs £20/pallet to move inventory between locations A and B. But with these rules in place, we have demonstrated that it is possible to automatically calculate the best action that you can take for any waste risk, reducing the decision making process from weeks to minutes.

Executing Actions

Once an action has been selected, the final pitfall comes at the execution stage. This is another black hole where many waste mitigation actions disappear for weeks at a time, resulting in the expiry clock ticking down past the higher-value actions. A robust business process is crucial for keeping track of in-flight actions.

The key elements of this process are ownership of the action, a timeline to complete an action and a process which requires the action owner to update the status of their action at regular intervals, usually each week. This enables the process owner to see when actions have been sat with an owner without progress for too many weeks, and follow-up to remove blockers or assign an alternative action. The system will also monitor if particular action owners are not executing their actions in a timely manner so that someone can follow-up and identify any issues that can be resolved to improve execution timeliness.

Automation Opportunities

At the start of this journey, this type of solution normally has an owner in each area of the business, such as a Waste Champion, who will use the tool to assign actions for each waste risk. As the maturity of the solution increases, it will become clear that there is no value to add to certain decision making and that automation can improve the efficiency of the process. The first type of automation is typically when there is only one action available, such as disposing/recycling of inventory past its expiry date, or donating inventory with just a few weeks left until expiry. More advanced automation can include automatically selecting an action when it clearly has the best financial benefit, or automatically selecting higher-value interventions when they are available. Automating these decisions decreases the time to assign an action to a waste risk, and also frees up user time to focus on value adding decision making.

Tracking Waste Management Actions

The final part of the process is a retrospective review of the actions taken on a monthly basis. Actions are recorded at the point of execution, enabling a view of the actions taken each month, the waste that was avoided, the revenue generated from that waste and the destination of the waste, including donations and disposals. This greatly simplifies and improves the accuracy of food waste and donation metrics. It also enables analysis of which products and/or locations are driving the most waste. With a report that shows the top 5 or 10 SKUs, you can prioritise resolving the root causes of the biggest issues, which are the most likely to have a viable business case. What we currently see is planning teams spending hundreds of hours a year manually assigning root causes to every waste line on the P&L, which is generally prioritised above actually preventing the waste by taking actions. By freeing up planning teams to tackle waste first, and prioritise root causing the biggest issues, you can reduce food waste in the most efficient and economical way.

By improving visibility of what will be wasted, making quick, data-driven decisions on the actions to take and having a robust process to make sure these are executed, it is possible to reduce finished goods food waste by up to 70%. This type of project in Win-Win-Win, with financial, sustainability and employee satisfaction benefits. On average, this solution has delivered 20X ROI for large food manufacturers we have worked with. We are so confident in what we do, we will deliver you a proof of concept project within 4-6 weeks, at cost price, to show you how much this solution could benefit your organisation.

Purpose AI

Purpose AI is an AI and Analytics Consultancy delivering data-driven solutions for complex Supply Chain and Commercial decision making. We work across the Consumer Products and Retail Industries and have worked with many Top 20 CPGs and Retailers in Europe and North America. Our USP is that we have developed industrialised solutions to common industry problems, reducing the time and costs to deliver value. But unlike SaaS providers, there is no licensing costs, we customise our solutions to your requirements and embed a strong business process to ensure they deliver value.